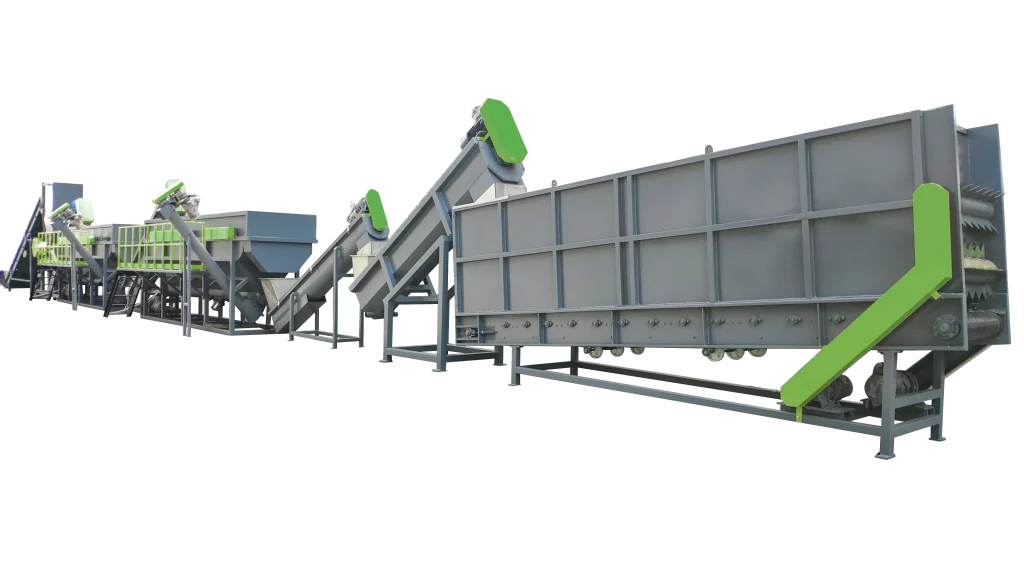

Plastic recycling washing line

This plastic recycling washing line is the core process that transforms plastic waste from “trash” into “renewable raw material.”

Product Specifications

- Capacity 300-1000 kg/h

- Material PP, PE, LDPE, HDPE Films

- Power 150-300 kW

- Pellet Size 2-5 mm

- Warranty 1 Year

Product Description

The process flow is as follows—

First, the de-labeling machine rotates at high speed to peel off PET labels from bottle surfaces. The bottles are then fed into a shredder and broken into flakes of around 3 cm. These flakes move into a high-friction washing machine, where coarse mud and adhesives are removed through intense friction.

The real cleaning takes place in the hot wash tank. Here, the flakes are soaked and agitated in an alkaline solution at temperatures above 80°C, chemically stripping away residual beverages, oils, and label adhesives. After two stages of rinsing and friction washing, the material finally passes through a high-speed centrifugal dewatering unit and a hot-air drying system—emerging as clean, dry PET/PVC/PE flakes.

This system delivers value in two key areas:

First, high separation efficiency. It achieves over 99% label removal and automatic separation of different materials, ensuring high purity for downstream pelletizing.

Second, low operating costs. Wastewater is recycled through sedimentation and filtration, reducing water consumption per ton by 70% compared to traditional processes. An integrated heat recovery system cuts hot-wash energy use by one-third.

What finally exits the discharge port is no longer waste—it is industrial-grade raw material ready for supply to fiber plants and packaging material manufacturers.