ABOUT US

Suzhou Beakeland Machinery Co.,ltd(BKL-MACHINE),Over 15 years of knowledge and experience in plastic recycling & reprocessing equipment which is the professional manufacturer of plastic washing machine and plastic pelletizing machine in Jiangsu, China.With worksite area of 4000 square meters and office 300 square meters and has more than 50 employees. Pursuing innovation and excellence, we specialize in plastic waste crushing, washing and drying line, turnkey plant for recycling varies plastics, plastic granulating line, Plastic waste shredding and crushing system,Plastic extrusion and customized equipment and components.

Why Choose Us

Company Advantages

About 160 sets advanced production facilities.More than 20 different sizes profile wires.

Wide range materials, include stainless and alloys.Big production capacity, more than 600MT/year.

About 20000 square meter plant, 120 experienced workers.

Independent R&D ability.

Our Product Advantages

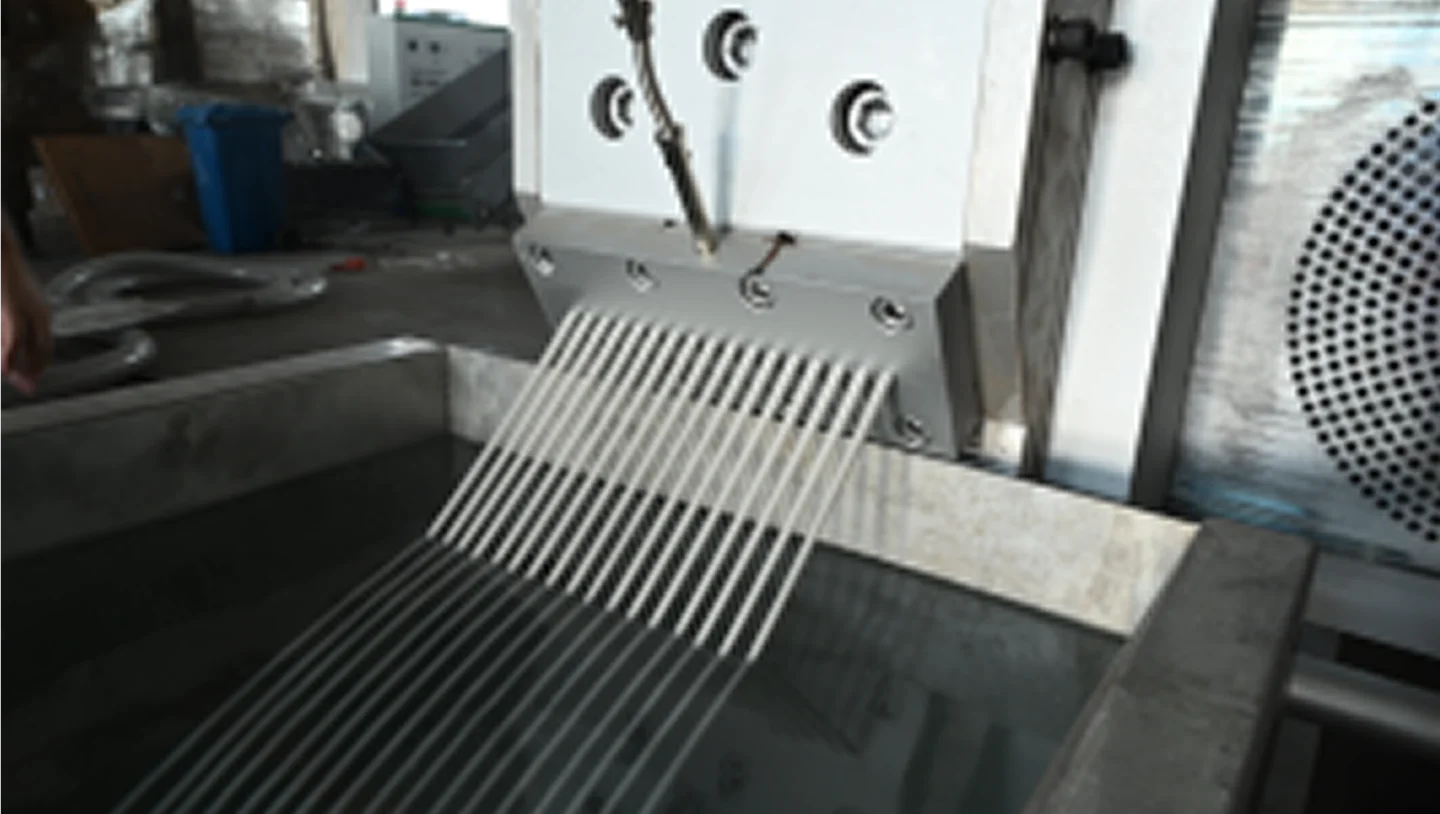

Self-supporting structure, high strength, and high rigidity.V type structure, anti-blocking design, easy to clean and backwash.

Uniform gap, fairly well precision and roundness; Low resistance drop and low maintenance cost.

Good flat panel surface; Good in filtration and fluidity;Good resistance to abrasion and corrosion, long working life.

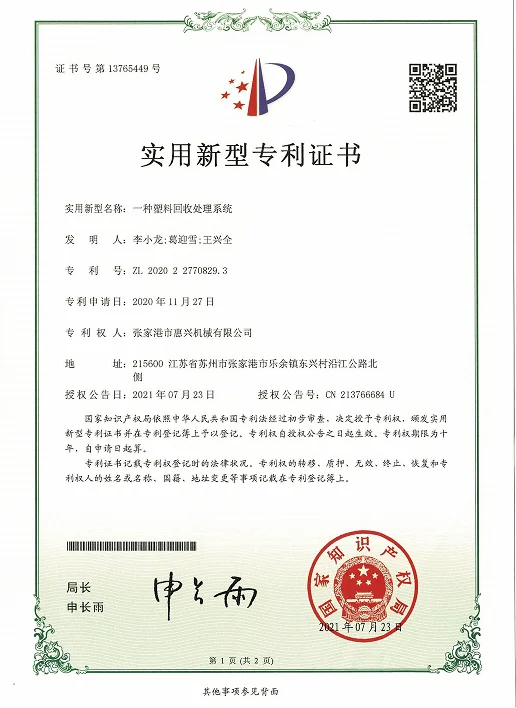

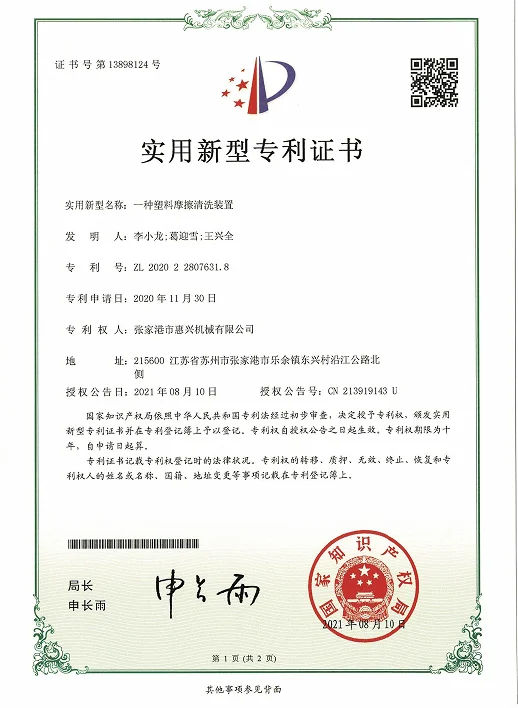

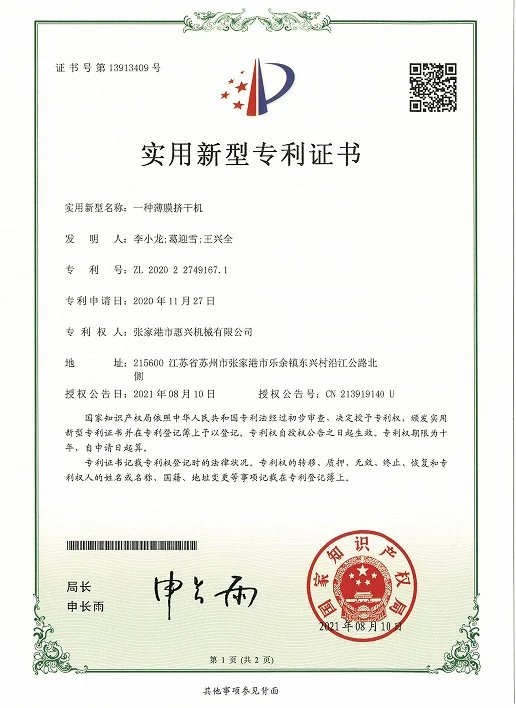

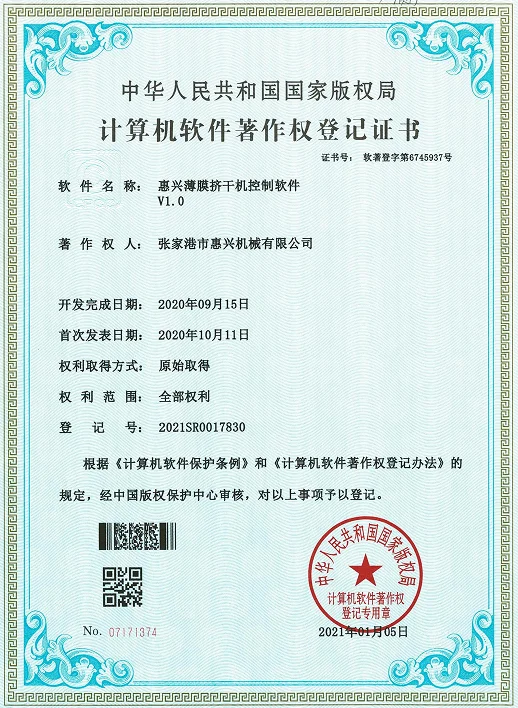

Certificate

Process Flow

Design And Planning

talk with the client to clarify the equipment's functions, output, product requests. design the structure and process in combination with market trends, and produce drawings and solutions.

01

Material Preparation

select material suppliers (steel, pipes, plates...) that meet the design standards.and the procurement of key components (such as motors, hydraulic systems, and electrical appliances)

02

Raw Material Cutting

laser cutting/flame cutting of sheet metal; lathes and milling machines are used to process functional structures such as holes and threads.

03

CNC Processing

applied cnc process on some key components like shaft of crusher, shredder, compactor knife seat of the plastic pelletizing line.

04

Bending And Forming

apply for steel plate material bending forming.like plastic washing tank body, screw loader tube, friction washer body...

05

Welding

welding is carried out by argon arc welding or electric arc welding. porosity is avoided through current/voltage control to ensure the strength of the weld seam.

06

Painting

painting the plastic recycling machine for enhance anti-rust capability and improve appreance quantity.

07

Assembly

assemble the frame and transmission components according to the drawings, connect the hydraulic pipelines and electrical circuits, and check the fit clearance and sealing performance. debug the parameters to the best state for all ready plastic recycling machines.

08

Inspection And Testing

visual inspection (paint film adhesion, weld flatness) and performance testing (power on and test the machine with materials as per customer requirements). ensure that the performance of the equipment meets the customer's requirements.

09